Can ship immediately

1. Description

The LED is optically coupled to an integrated high gain photo detector. Minimized propagation delay difference between devices makes these optocouplers excellent solutions for improving inverter efficiency through reduced

switching dead time.

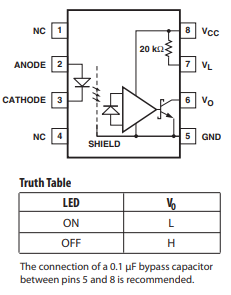

An on chip 20 kΩ output pull-up resistor can be enabled by shorting output pins 6 and 7, thus eliminating the need for an external pull-up resistor in common IPM applications.

Specifications and performance plots are given for typical IPM applications.

2. Features

1. Performance specified for bommon IPM applications over industrial temperature range: -40°C to 100°C

2. Fast maximum propagation delays

tPHL = 480ns

tPLH = 550ns

3. Minimized Pulse Width Distortion

PWD = 450 ns

4. 15 kV/µs minimum common mode transient immunity at VCM = 1500 V

5. CTR > 44% at IF = 10mA

6. Safety approval:

UL Recognized

-3750 V rms / 1 min. for HCPL-4506/0466/J456

-5000 V rms / 1 min. for HCPL-4506 Option 020 and HCNW4506 CSA Approved

IEC/EN/DIN EN 60747-5-2 Approved

-VIORM = 560 Vpeak for HCPL-0466 Option 060

-VIORM = 630 Vpeak for HCPL-4506 Option 060

-VIORM = 891 Vpeak for HCPL-J456

-VIORM = 1414 Vpeak for HCNW4506

Functional Diagram

Description:

1. At a free air temperature above 90°C, it decreases linearly at a rate of 0.8 mA/°C.

2. At a free air temperature higher than 90°C, it decreases linearly at a rate of 1.6 mA/°C.

3. At a free air temperature above 90°C, it decreases linearly at a rate of 3.0 mW/°C.

4. At a free air temperature above 90°C, it decreases linearly at a rate of 4.2 mW/°C.

5. The current transfer ratio expressed as a percentage is the ratio of the output collector current (IO) to the LED forward input current (IF) multiplied by 100.

6. The device is considered a two-terminal device: Pins 1, 2, 3, and 4 are shorted together, and pins 5, 6, 7 and 8 are shorted.

7. According to UL 1577, each optocoupler is verified by applying an insulation test voltage ≥4500 V rms for 1 second (leakage Detection current limit, II-O≤5µA).

8. According to UL 1577, each optocoupler is verified by applying an insulation test voltage ≥4500 V rms for 1 second (leakage Detection current limit, Ii-o≤5 µA).

9. According to UL 1577, each optocoupler is verified by applying an insulation test voltage ≥6000 V rms for 1 second (leakage Detection current limit, II-O≤5 µA).

10. If applicable, perform this test before the 100% production test shown in the IEC/EN/DIN EN 60747-5-2 insulation-related characteristics table.

11. Pulse: f = 20 kHz, duty cycle = 10%.

12. The internal 20kΩ resistor can be used by shorting pins 6 and 7 together.

13. Due to the tolerance of the internal resistor, and since the propagation delay depends on the value of the load resistor, the performance can be improved By using an external 20kΩ 1% load resistor. See Figure 8 for more information on how propagation delay varies with load resistance.

14. RL = 20kΩ, CL = 100 pF load represents a typical IPM (Intelligent Power Module) load.

15. For more information, see Option 020 data sheet.

16. Use a 0.1 µF bypass capacitor between pins 5 and 8 to improve performance by filtering power line noise.

17. Under the same test conditions, the difference between tPLH and tPHL between any two devices.

18. The common mode transient immunity in the logic high level is the maximum allowable dVCM / dt of the common mode pulse VCM to ensure The output will remain in a logic high state (ie VO>3.0 V).

19. The common mode transient immunity in the logic low level is the maximum allowable dVCM / dt of the common mode pulse VCM to ensure The output will maintain a logic low state (that is, VO <1.0V).

20. Pulse width distortion (PWD) is defined as |tPHL-tPLH| for any given device.

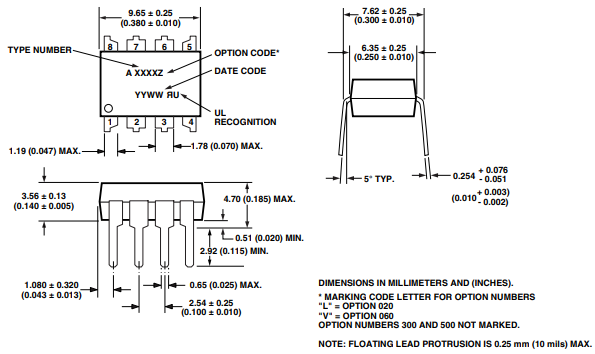

Package Outline Drawings